BOKEQI MACHINERY ·

Expert on fine stone concrete pump

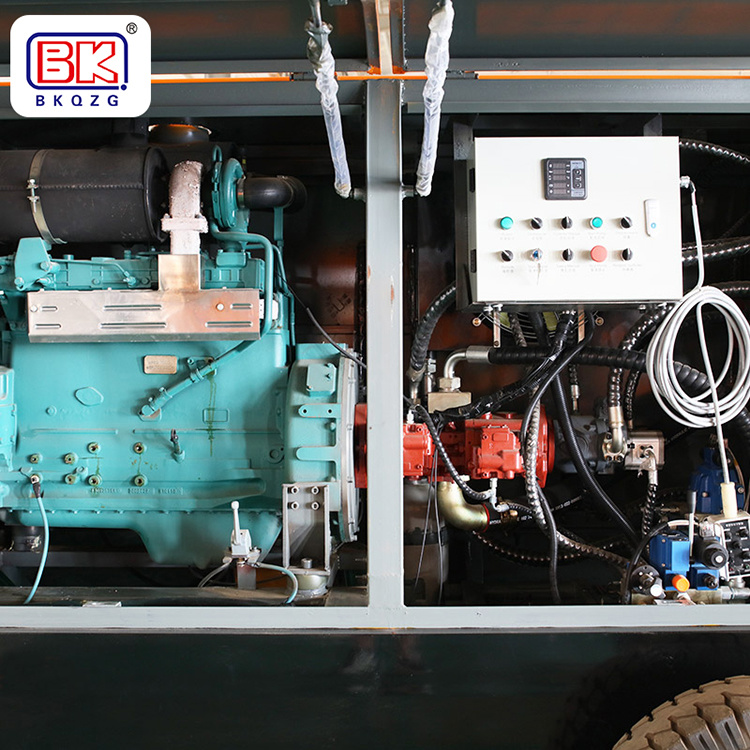

80-type fine aggregate concrete pump construction site

The fine aggregate concrete pump is now widely used on construction sites. It is easy to operate and convenient to move, helping construction teams solve the problem of material delivery to high-rise buildings. To ensure that the concrete pump serves us better, let's discuss the daily maintenance issues of the pump truck.

80-type fine aggregate concrete pumpDaily maintenance

(1) Check the hydraulic oil level and quality. The oil should be light yellow and transparent, without emulsification or turbidity; otherwise, it should be replaced.

(2) Check the working condition of the lubrication system. The progressive oil distributor indicator rod should move back and forth, and there should be lubricating oil overflowing at lubrication points such as the S pipe swing arm end bearing position and the mixing shaft bearing position. Manual lubrication points should be injected with grease at each shift, and the water tank should be filled with clean water.

(3) Check the concrete piston. It should be well sealed, with no mortar seeping into the water tank.

(4) Check the cutting ring. The gap between the glasses should be normal (within 2mm).

(5) Check whether the functions of various electrical components are normal.

(6) Check whether the distribution valve switching and the mixing device's forward and reverse rotation are functioning normally.

(7) Check the exterior of the cooler. If there is dirt, clean it immediately; otherwise, it may cause the oil temperature to overheat.

(8) Check the vacuum gauge indication, which should be within the green zone (vacuum not exceeding 0.04). Generally, the oil suction vacuum should be less than 0.02MPa.

(9) Check the wear of the concrete pipeline by tapping, and check whether the joints of each pipeline are well sealed.

(10) Check whether there are any oil leaks or seepage in the hydraulic system.